What is Blindex® Strengthened Glass?

The Blindex® strengthened glass is manufactured from the common glass (float), which means it has all features: transparency color and parallel surface.

It is produced by heat treatment, known as "tempering”, that confers resistance to bending and mechanic impacts much more than ordinary glass, and heat resistance related to its original glass, supporting variations up to 200ºC.

The purpose of quenching is to provide high compressive stressed areas of the glass surface and corresponding high tensile stresses in the center there of. By breaking it up, it is fragmented into small pieces, rounded and slightly sharp.

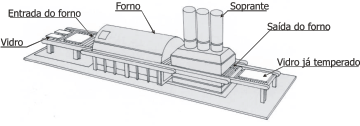

Blindex® Tempering Process

The glass is cut in the shape and size as desired. Then, it goes to lapidating and the needed holes. After this operation is complete, the piece goes for tempering. The glass is placed horizontally in the oven, ensuring that the glass has the undesirable marks clamp, and subjected to 600ºC temperature. At that point receives a rough cooling through a quench playing pressured air, causing the state of tension.

The Blindex® strengthening process is irreversible, in other words, once strengthened the glass cannot suffer any kind of trimming, cutting or drilling.

The strengthened is according to ABNT NBR 14698:2001.

The Blindex® safety strengthened glass is provided with appropriate internal tensions which confer mechanical strength; about four times that of ordinary glass.

The glass fragments into small pieces less sharp than the common glass.

Properties

- Allowable bending stress: s = 60MPa.

- Resistance to thermal differential = 220ºC (not indicated as fire resistant glass)

- Density: 2.500kg/m3.